Whilst the origins of stainless steel as an alloy date back to early in the 20th century, the actual origins of the process required to manufacture all steels dates back as early as 1740.

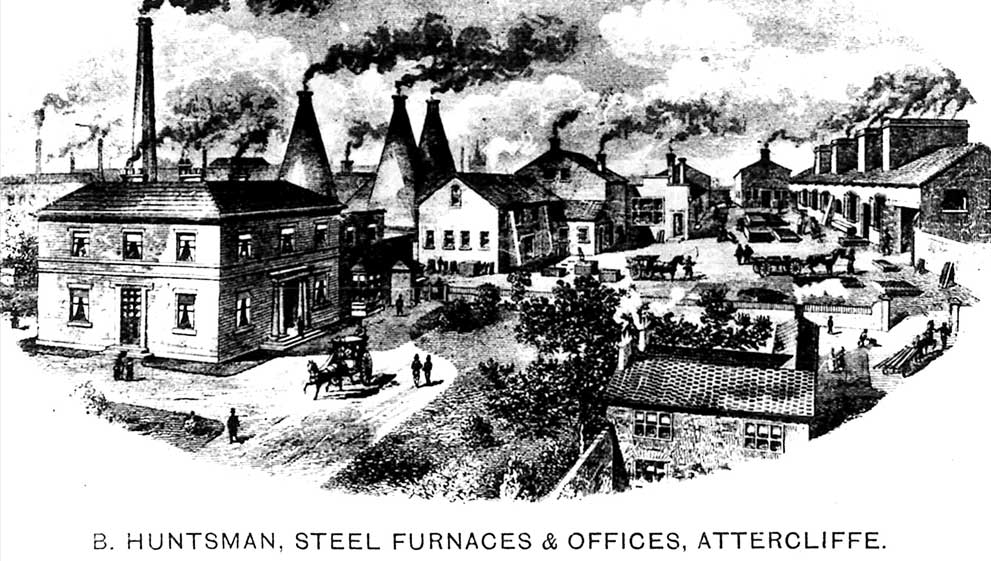

Attributed to the English manufacturer and inventor, Benjamin Huntsman (1704 – 1776) the process involved the casting of steel in crucibles made of clay pot using a mixture of iron and high carbon steel such as pig iron, with added flux material such as sand, glass or ash. Huntsman’s process was unique in that it used coke, instead of the previously used coal and wood, to achieve much higher temperatures allowing the iron to fully dissolve into the steel.

Huntsman’s manufacturing technique also involved a slower warm up and cool down of the material that allowed greater diffusion of the carbon element, resulting in a higher quality and consistent finished material, that was stronger and harder than previous forms of steel.

Huntsman’s factory could produce around 34 pounds of blistered steel per crucible, which was exported in large quantities to cutlery manufacturers in France. It was when these French manufactures started exporting those products back into England, that the process caught the attention of the Sheffield cutlery manufacturers.

Initially, the Sheffield manufacturers lobbied government to prohibit the export of this new steel, an attempt that failed. Sadly Huntsman never patented his process for manufacturing the steel, and legend has it that Sheffield iron founder Samuel Walker stole the process in 1750, after posing as a beggar and asking to sleep in the warmth of the foundry for the night.

Do you have to wonder what Huntsman’s lab was like back in 1740 when he made the discovery? Now-a-days you’ll find the Stainless Steel that his process was eventually born out of in many applications, like our Stainless Steel Laboratory Sinks.