A groundbreaking electrochemical process developed at Georgia Tech could transform stainless steel into a powerful tool against bacterial infections — all without contributing to the growing crisis of antibiotic resistance.

Why Stainless Steel Matters

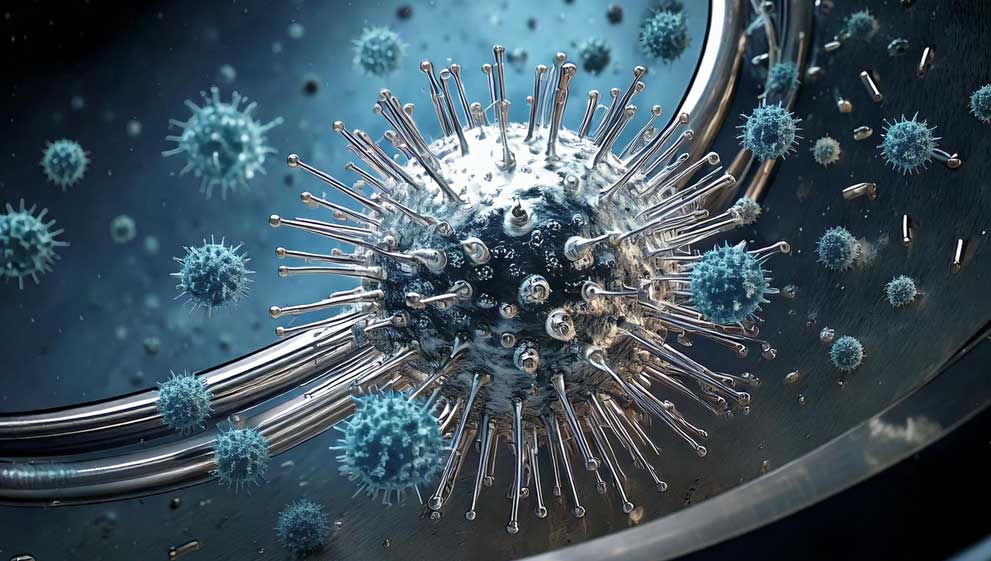

Stainless steel is already a mainstay in hospitals, kitchens, and industrial settings. But this innovative process amplifies its usefulness by leveraging copper's natural antibacterial properties. Researchers etched the surface of stainless steel to create nano-sized, needle-like structures capable of puncturing bacteria, then enhanced it with a thin copper coating.

This dual-action surface doesn’t just kill bacteria - it excels at doing so:

- 97% reduction of Gram-negative E. coli

- 99% reduction of Gram-positive Staphylococcus epidermidis

Tackling a Global Challenge

Drug-resistant infections claimed 1.27 million lives in 2019 and contributed to nearly 5 million additional deaths. The need for antibiotic-free solutions is urgent, and this copper-coated, nano-textured stainless steel is a promising candidate.

Efficient, Cost-Effective, and Life-Saving

Despite copper’s exceptional antibacterial properties, its cost limits widespread use. This method uses only a thin layer of copper ions, making it affordable without compromising effectiveness. The process can be seamlessly integrated into existing industrial techniques, potentially revolutionising how we combat bacteria on common surfaces.

“We aimed to develop an antibiotic-free bactericidal surface effective against Gram-negative and Gram-positive bacteria,” explained lead researcher Anuja Tripathi. “The nano-textured stainless steel alone was effective, but the copper coating significantly enhanced antibacterial activity.”

Versatile Applications

This innovation could be used to improve the safety of:

- Medical tools: Scissors, tweezers, and implants.

- Shared surfaces: Door handles, railings, and sinks.

- Food service equipment: Storage containers and preparation tools.

Tripathi sees potential for even broader applications, including medical implants and solutions for persistent bacterial outbreaks like the recent E. coli contamination in Calgary, Canada.

Future Prospects

The team is now investigating whether the copper-coated, nano-textured stainless steel can combat other harmful pathogens. Tripathi remains optimistic:

“If we can effectively eliminate *E. coli*, we stand a good chance of eradicating many bacteria on surfaces,” she said.

This innovation underscores the vital role stainless steel could play in safeguarding public health, offering a durable, efficient, and cost-effective solution to one of the world’s most pressing challenges.

DSM already makes use of the anti-bacterial properties of Stainless Steel, like in our Stainless Steel Laboratory Sinks or Stainless Steel Vanity Tops.