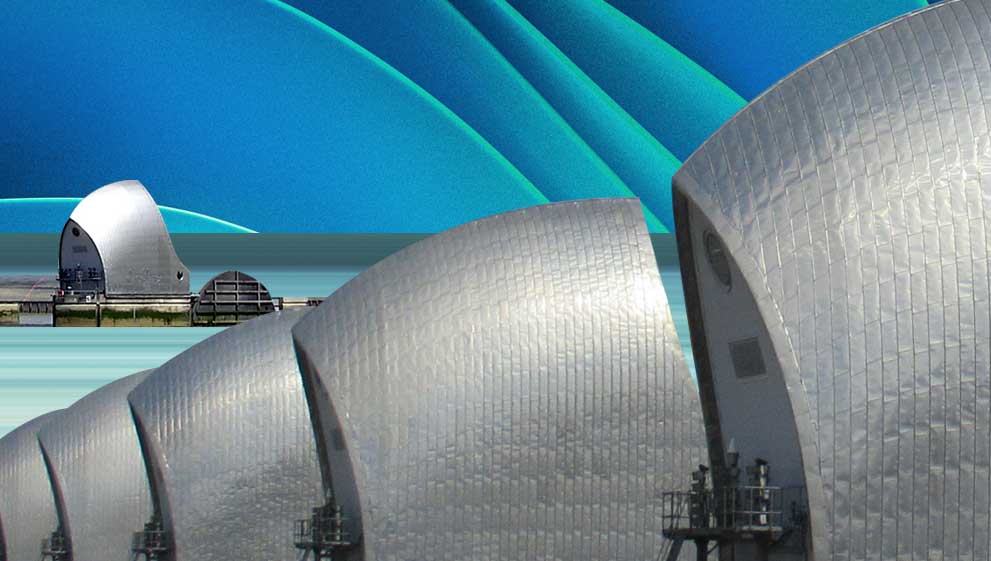

On the 8th of May, in 1984, the £535-million Thames Barrier was officially opened by Her Majesty Queen Elizabeth II and the Duke of Edinburgh (it was operational since 1982). Construction of the impressive and unique flood control structure, which spans 520 metres across the river Thames at Woolwich Reach in East London. The Thames Barrier is one of the largest movable flood barriers in the world.

When raised, the main gates stand as high as a five-storey building and as wide as the opening of Tower Bridge. Each main gate weighs 3,300 tonnes. Without the Thames Barrier, the Houses of Parliament, the O2 arena, Tower Bridge and areas of Southwark, Beckton, West Ham, Whitechapel would all be submerged in flood water.

The barrier consists of ten stainless steel piers, an ideal material to use for structural support, due to it high strength even when placed under high tensile stress. In addition to its high strength, stainless steel is also highly resistant to corrosion. This means that the structures are low maintenance, and unlikely to be damaged by exposure to rain or river water. This is important as it is constantly exposed to both air pollution and water, yet the stainless steel making up the structure has prevented any damage from occurring.

Our stainless steel products also exploit the the same properties that Stainless Steel possesses, from it's resistance to corrosion to it's high tensile strength. It really is the perfect material for so many applications: from kitchens to laboratories, from worktops to sinks.

We were in London the other day and saw someone struggling to swim across the Thames… We tossed them a bar of soap and they washed ashore.