Glass and stainless steel have always complimented one another aesthetically, whether is a glass splash guard on a laboratory sink, or a glass panel in a stainless balustrade. The problem has always been joining the two very different materials together.

From a layman’s perspective, joining the two inert material together might look straight forward, but because of their very different physical and thermal properties, particularly with regards to rates of expansion and contraction, any bond can be problematic, which is why the glass is normally held by a suitable channel or gripping system.

Attempts have been made in the past to weld stainless steel and glass together, but because of metal greater level of expansion and contraction, most attempts result in the glass cracking. Similarly with adhesive based techniques, the continuous expansion and contraction of the metal can cause the glass to ‘creep’ out of position.

It is therefore something of a breakthrough that researchers at Heriot-Watt University in Edinburgh have developed a technique that successfully bonds glass to stainless steel and other metals.

The space age method involves firing a tiny ‘lightning balls’ of laser light through the glass to the join with the metal. The ultra fast laser system sends these million watt pulses at around one trillionth of a second – by focusing these pulses at the join, the intense heat is sufficient to melt both materials, but short enough to prevent expansion of the metal.

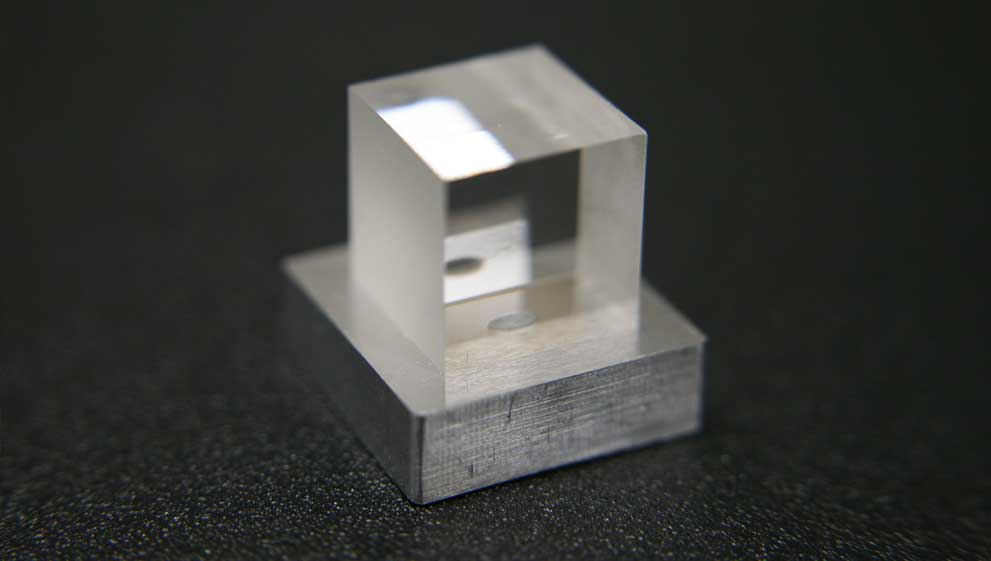

Glass is only the tip on the iceberg however, the Heriot-Watt researchers have also been able to weld sapphires and quartz to stainless steel, titanium and aluminium, opening up a huge range of technological possibility for this new technique.

Whilst we can’t weld glass to our stainless steel products at DSM, we can add channels to our Laboratory Sinks to hold glass splash screens, and can also supply our Stainless Steel Cupboards with glass doors if required.